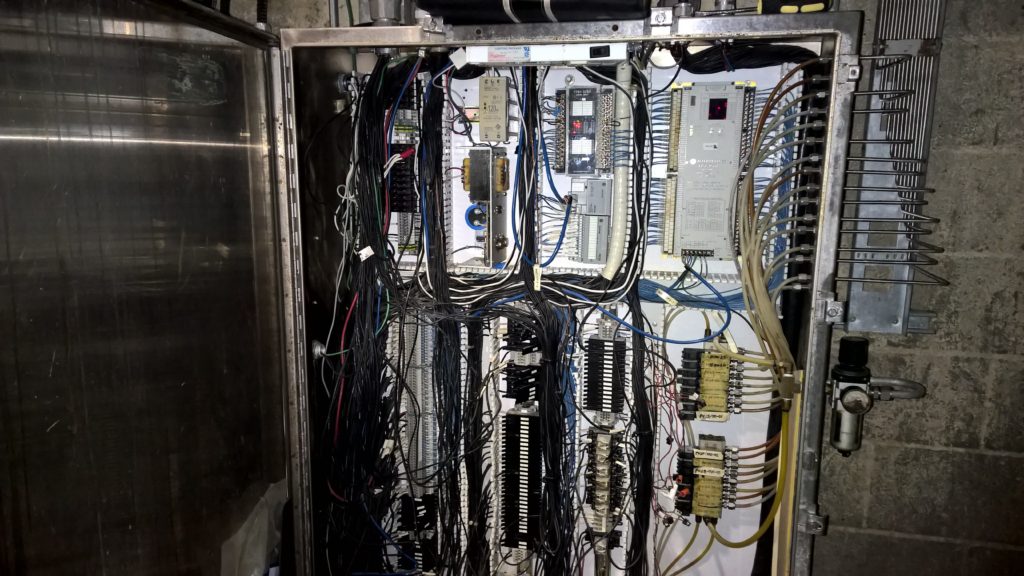

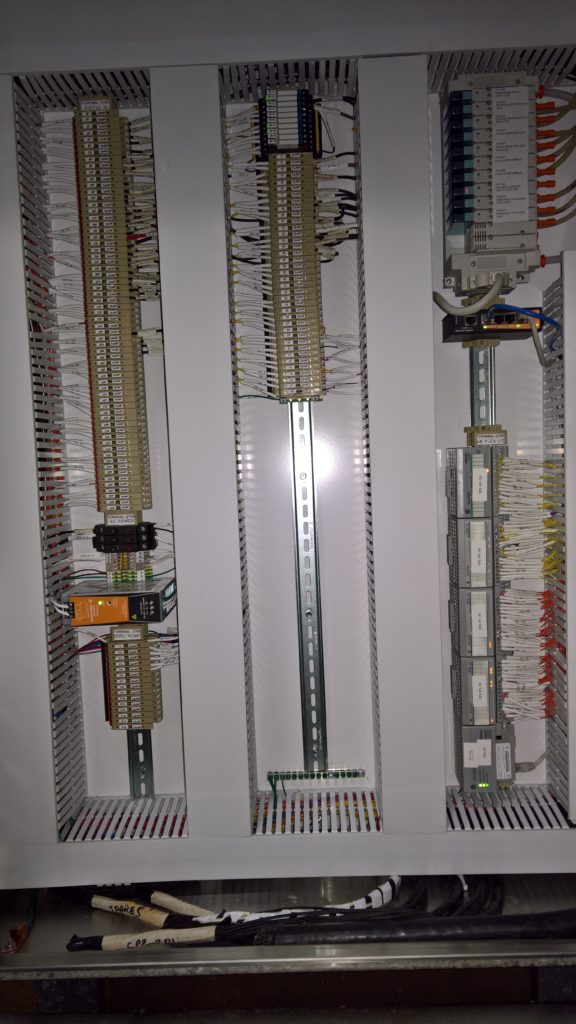

Impel recently completed stage 2 of a 4-stage facility upgrade for a local Alberta food producer. Both stage 1 and stage 2 involved upgrading the obsolete PLC5 control system to ControlLogix and remote I/O. Stage 2 included the replacement of another PLC5 CPU rack and its rack I/O along with replacement of an old remote I/O cabinet and its even older PLC2 hardware (other PLC2 hardware inside a second remote I/O panel was also replaced). The replacement remote I/O hardware used was Ethernet based Flex I/O. The upgrade timeline allowed the client to minimize downtime while reducing complexity and eliminating a number of PLC CPUs. Existing PLC5 code was converted from RS-Logix 5 to Studio 5000; its I/O was re-addressed and then integrated into a new ControlLogix Processor.