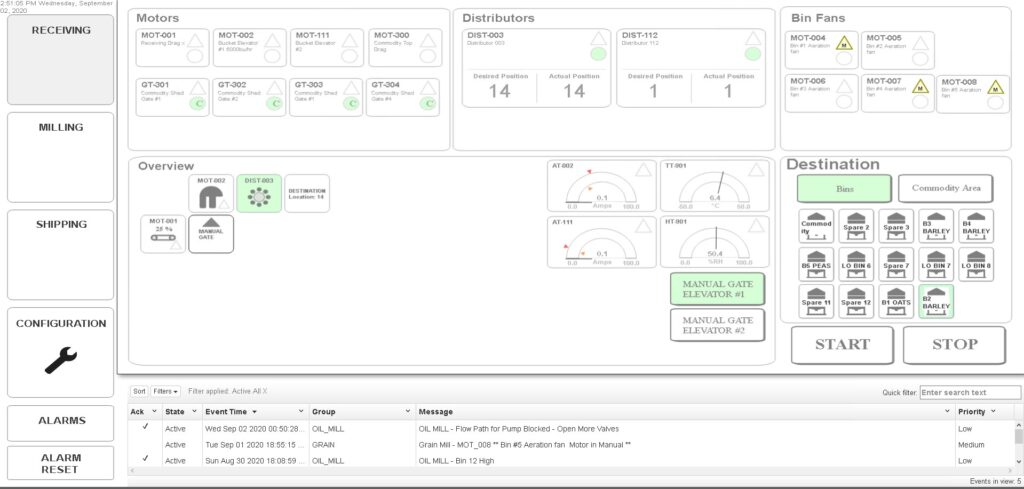

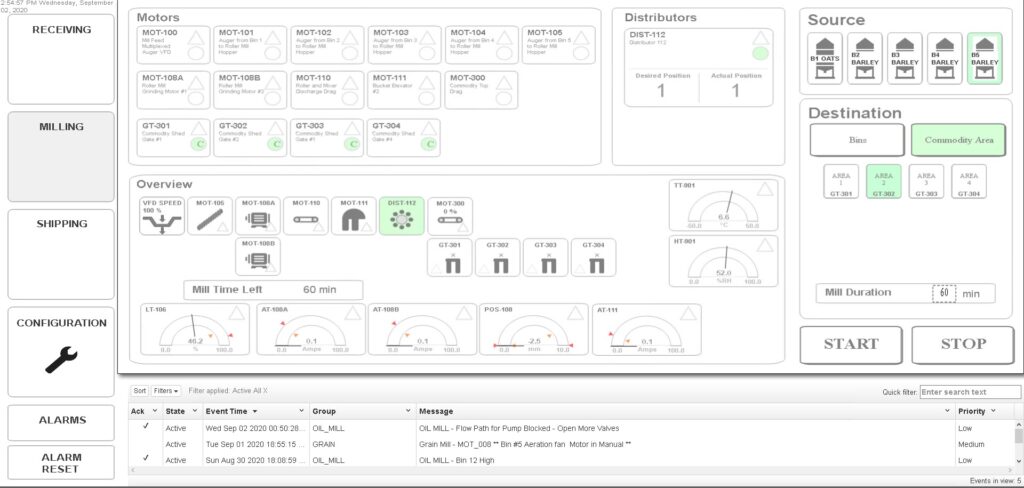

Impel recently commissioned a grain milling system for a local Alberta producer. The system consisted of three main areas, receiving, milling, shipping and has over 50 motors. Impel designed the PLC control system along with the 600VAC motor contactor and VFD panels which control the various legs, drags, and equipment motors. To prevent any plugs within the grain handling system, current transducers were used to monitor the motor amperage of each bucket elevator and control the speed of product flowing into those elevators. Two 14-Port distributors were automated as part of the flow path selection. Impel also chose to use Vega radar sensors to provide real time level sensing, used to maintain a consistent product level flowing into the roller mill. Impel also provided our own 1-wire converter solution which allows the PLC read temperature and humidity data from digital 1-wire cables inside the numerous silos. FactoryTalk View Studio SE was utilized for the HMI using FactoryTalk ViewPoint web clients, this allows the HMI to be accessed through a standard web browser whether on a PC or mobile device. The HMI graphics developed use the current best practices in design; providing an easy to use, minimalistic interface, and is intended to reduce operator error while still providing unrestricted control of the system.