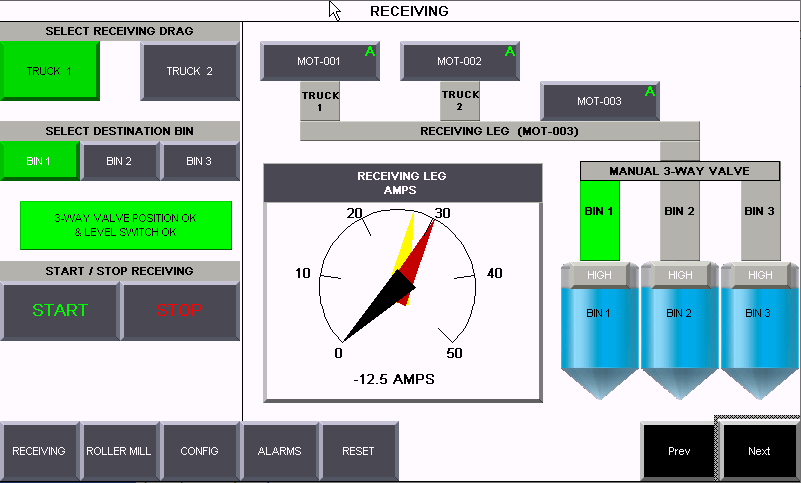

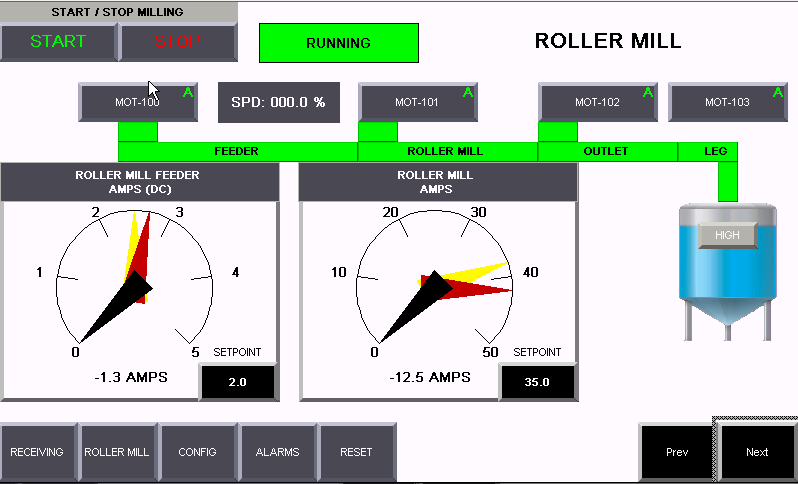

Impel systems recently designed a small milling control panel for a local producer. The system consists of a receiving area and a roller mill, the control system monitors the motor amperage of the receiving elevator as well as the roller mill main motor and its feed motor. Automated VFD speed control of the roller feed motor was implemented in which both the feed motor and roller motor amps are used, the allows for maximum throughput regardless of grain type without operator adjustment. Bin level switches allow for the system to automatically stop and cleanout when the bins are full or when the mill empties its supply bin.